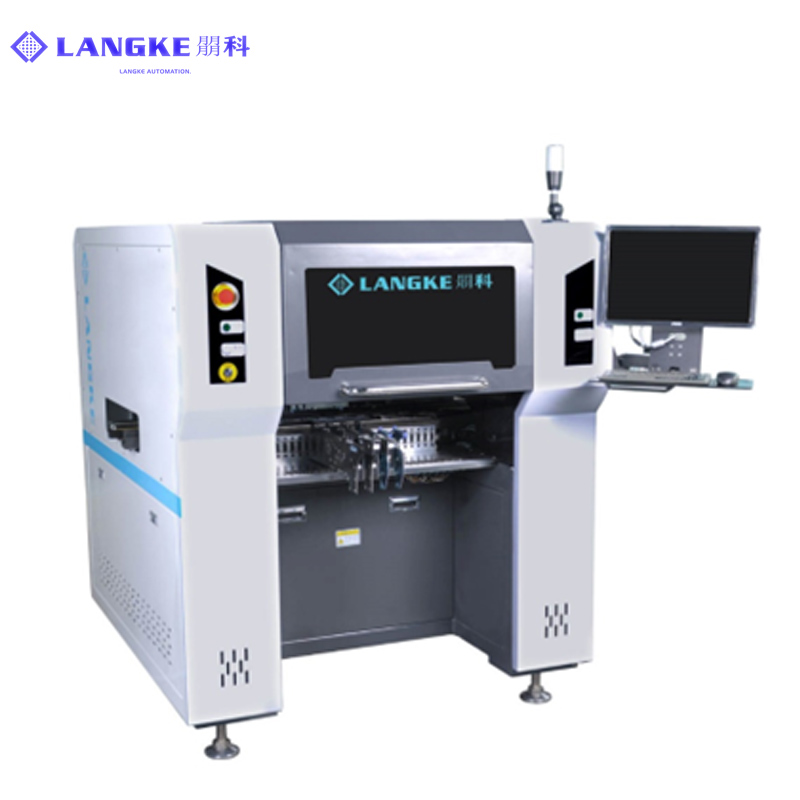

SMT DOB pick and place machine for high and big components

Feature

1.Inline Automatic production method, help customer to save labor cost.

2.R&D linear maglev motor: faster, higher and better.

3.New type of machinery system, place electrolytic capacitor, inductor and other materials are not easy to jam.

4.R&D software system, easy to operate and learn.

5.You can use feeder and bowl feeder at the same time, M type capacitor, Horizontal capacitor, inductor etc. can be mounted.

Application

DOB products, LED, LED driver, Small electrical circuit board, such as appliances, digital products, this one machine can solve well the base cost and speed problem.

Specification:

Model | LK-D8 |

pcb max size | 600(X)*420(Y)*14(Z)mm |

Z axis moving area | 45mm |

component height | 20mm |

max placement speed | 15000CPH |

average placement speed | 7000-15000CPH |

position accuracy | 0.1mm |

nozzles buffer area | 4.0 |

power | 220V/50Hz |

control method | computer |

air pressure | 0.65-0.75Mpa |

average power | 2KW |

feeding | electric feeder |

mount head driving motor | linear motor |

mount head | 8 heads |

number of feeders | 24 pcs |

component angle | any angle |

air source | vacuum pump |

OS program method | R&D by Langke, easy to learn and understand, Vision program |

weight | 1000KG |

dimension | 1320mm*1550mm*1520mm |